The technical design of the XM1 riser is based on four key points:

• Composite frame structure in aluminum/carbon.

• Use of hydraulics to dampen vibrations.

• Decisive increase in the percentage performance of the riser and improvement of the limb’s performance.

• Ease in the adjustment of the arc’s power, the ideal measuring of the tiller and limb alignment.

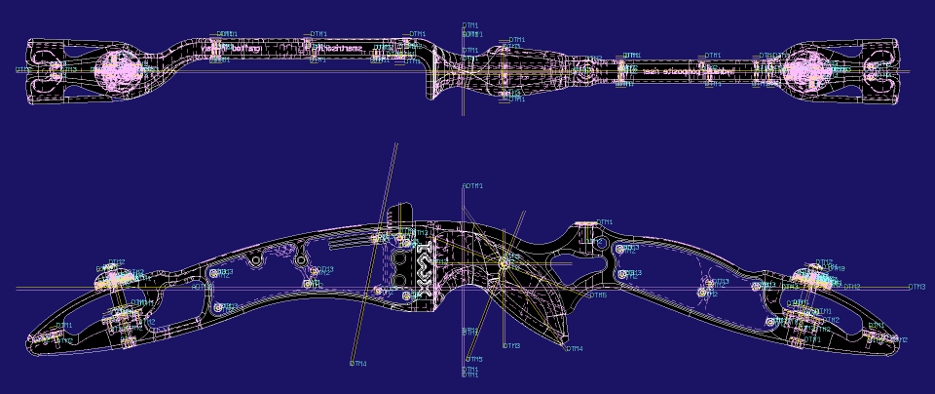

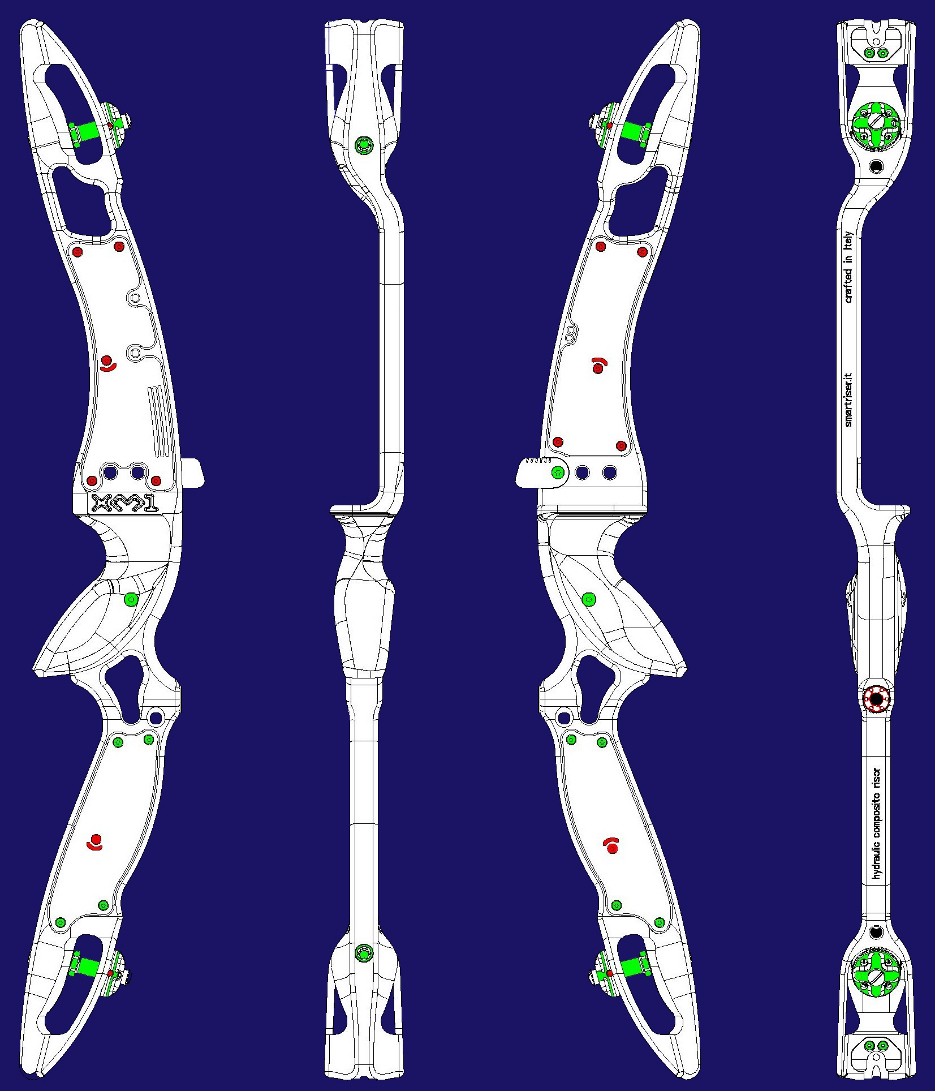

1. The metal frame is obtained by CNC milling from a 10 kg bar of Anticorodal aluminum alloy. Once the operation is complete, an extremely lightweight piece is obtained, but still unusable, without the addition of unidirectional carbon plates also CNC milled with values by the hundredths digit. After the coloring process is carried out by anodic oxidation, work on the frame is resumed by means of specific equipment on CNC machines in order to prepare the surface for bonding and to allow a centesimal tolerance of forced coupling to the carbon plates. These plates, glued to the riser by means of a bi-component epoxy structural adhesive, after a cycle of approximately sixty hours of pressure, become permanently joined to the metallic frame by material fusion and can no longer be disassembled. Araldite®, the adhesive used in the process, develops a bond strength of 20 N/mm². Because each plate rests on an area of 820 sq. mm, it results in 1,670 kg of axial bond strength produced for each element. The carbon parts, inserted in the structure with perfectly oriented fibers, have a tensile strength 15/20 times greater than that permitted by aluminum. Twelve of the twenty Torx screws in stainless steel present are blocked with the Loctite™ adhesive. They are necessary for holding the carbon plates pressed firmly in position during the polymerization of the adhesive, and for fastening the carbon onto equipment to coupling values during the milling process. The eight screws on the bottom plates - see figure – also serve the purpose of additional weight kits and are the only ones present on the plates that are removable. The tightening of the Torx screws are performed with torque wrenches in order to obtain absolute uniformity of pressure.

(locking screws in the red color - removable and adjustable screws in the green color.)

2. HFVD System. The XM1 is a hydraulic/composite riser which, by exploiting both the laws of fluid mechanics and that of the higher capabilities of carbon, reduces the high frequency vibrations which develop on the arch structure at the moment of the arrow’s release. There are four sealed chambers in the riser, two at the top and two at the bottom. These chambers, internally classified as “tubs”, with a total capacity of 70 cc. and conveniently filled up to a level equal to 80% of the internal volume, may contain various technical fluids of various viscosities (these liquids vary in degree of viscosity and density). During the release of the arrow, the vibration which takes over the structure “shakes” the fluid present inside. This movement allows the dissipation in the wall-layers of the high-frequency vibration that is built up during the shot. The dissipation of the vibration is also favored by the presence of carbon elements in the structure. In fact, this material has much higher capabilities for this kind of performance than that of aluminum. The results achieved are a drastic reduction of vibrations in the release phase with consequent lower muscle fatigue of the athlete, and a characteristic reduction of noise.

3. The support area of the limb is superior to other risers on the market, and is shaped in such a way that it can obtain a riser/limb contact surface that is more wide and constant with the amount of area involved, regardless of the change of the limb’s inclination. The particular design of the support surface thus allows a dual advantage: on the one hand, by avoiding passive forces from unloading on unnecessary areas during action, we obtain an increase of performance directly from the limb; while on the other hand, it best preserves the structural integrity. This will allow you to achieve a high efficiency of the structure that is also guaranteed by the extreme inherent rigidity of the XM1 riser. The overall performance, or rather the ratio between the potential elastic energy of the limbs and that actually released to the arrow, has been officially tested and its result was 79.44%, the highest value obtained so far among risers on the market. This value tends to increase, contrary to what occurs with other risers, when the installed power increases. The final performance achieved is a rare consistency in the values of maximum efficiency of ideal brace height, much higher compared to other projects.

4. With the QuickClick System you can easily find the correct setting of your power and tiller values, without the use of keys and without removing the limbs. The adjustment is achieved simply by rotating the upper disk of the QuickClick with your fingers, which has a rotation segmented by precise mechanical clicks. Each 90° click of the disk corresponds to a variation of +/- 0.5% of the load according to the power of the limb used. As an accessory, the QuickClick group is also available with an equipped safety lock by means of a locking grub screw.